Ensuring Product Integrity - A Deep Dive into Geometric Steels' Packaging Practices

Introduction:

In the realm of manufacturing, precision isn't confined to the production line alone. It extends to every aspect of the product lifecycle, including packaging. At Geometric Steels, we understand that the journey of our roofing, ventilation, secondary material, and safety solutions doesn't end when they leave our facilities. Ensuring that our products reach our customers safely and in pristine condition is a commitment we take seriously. In this blog, we'll explore the meticulous packaging practices we employ to safeguard the integrity of our offerings, both for domestic transportation and export.

We will explore the following points:

Packaging Practices for Domestic Transportation

Packaging Practices for Export

Packaging Practices for Roofing Solutions

Packaging Practices for Ventilation Solutions

Packaging Practices for Secondary Material Solutions

The Importance of Packaging

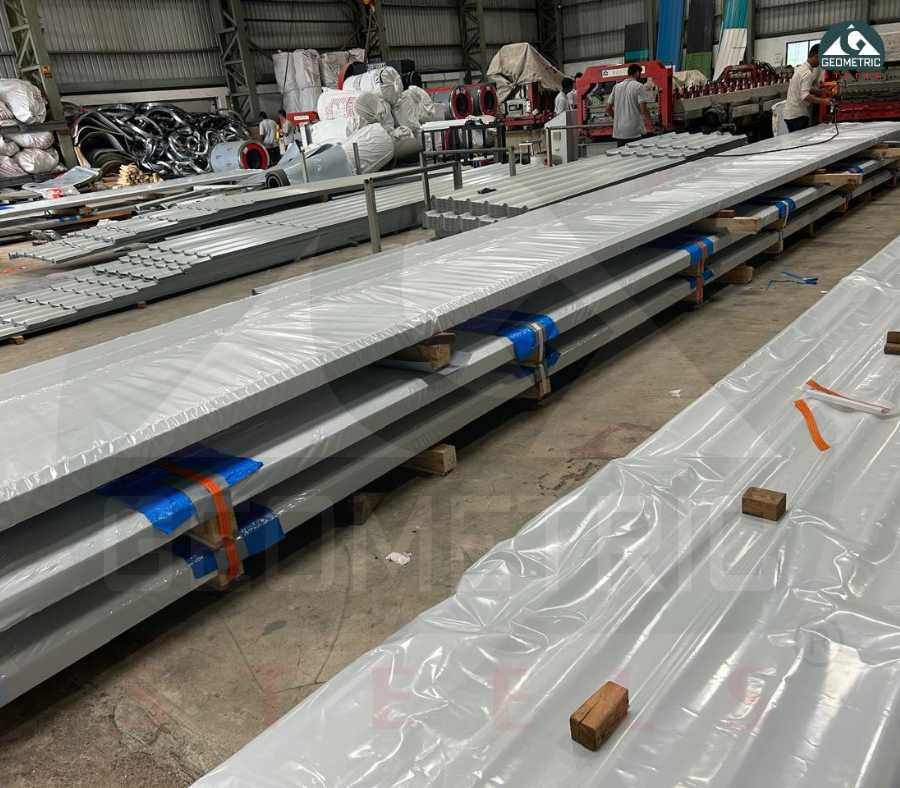

Packaging serves as the first line of defence for our products during transit and storage. It not only protects them from external elements but also plays a crucial role in preserving their quality and functionality. At Geometric Steels, we recognize that the right packaging can make all the difference, ensuring that our customers receive products that meet their expectations every time.

Packaging Practices for Domestic Transportation

For domestic shipments, our packaging practices are designed to withstand the rigors of road and rail transport. We utilize sturdy materials and robust construction methods to ensure that our products arrive at their destination in pristine condition. Each package is carefully labelled and tracked to facilitate smooth logistics operations and minimize the risk of damage or loss.

Packaging Practices for Export

When it comes to export shipments, we go the extra mile to ensure that our products are well-protected for long-distance travel. Our export packaging practices adhere to international standards and regulations, taking into account factors such as climate conditions, handling procedures, and customs requirements. We employ advanced packaging materials and techniques to safeguard our products against moisture, shock, and vibration during transit. Each export package is meticulously inspected and certified to meet the highest quality standards, providing our customers with peace of mind no matter where they are located.

Packaging Practices for Roofing Solutions:

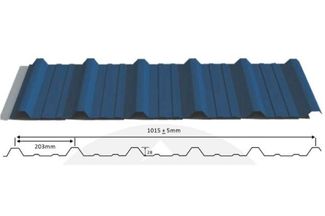

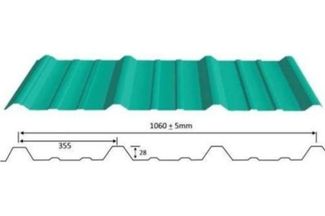

1. Colour Coated Profile Sheets:

Each ribstrong and bigspan profile sheet is carefully wrapped and secured to prevent any damage during transportation. We utilize high-quality materials that shield the sheets from moisture and mechanical stress.

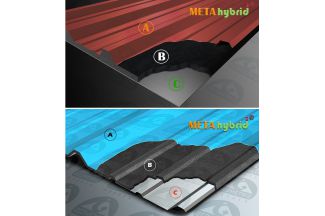

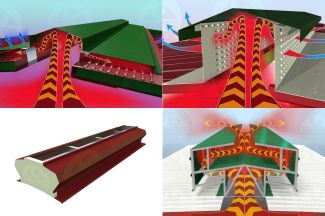

2. Metahybrid Thermal Insulated Roofing Sheets:

These pre-assembled sheets undergo meticulous quality checks before packaging. They are securely fastened and cushioned to prevent any displacement or damage during transit. Additionally, special attention is given to ensure that the insulation layers remain intact and effective.

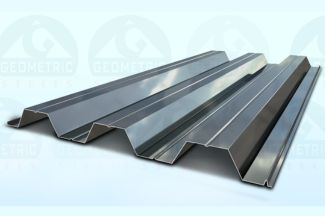

3. Aluminium Profile Sheets:

To prevent scratching or denting, our aluminium profile sheets are packaged with foam padding and reinforced corners.

4. Skylight Polycarbonate Roof Sheets:

These delicate sheets are packaged with utmost caution, utilizing shock-absorbent materials to prevent cracking or chipping during transit.

5. Stone Coated Roof Tiles:

Each type of tile is individually wrapped and cushioned to prevent breakage. We employ specialized packaging techniques to ensure that even the most intricate designs arrive intact.

6. Accessories:

Flashing and crimp curves are packaged in sturdy boxes, with ample padding to prevent deformation or bending.

Packaging Practices for Ventilation Solutions

1. Airflow Ridgevents:

These pre-assembled units are carefully packaged to protect delicate components such as bearings and vanes. Custom-designed packaging ensures that they remain secure and functional during transit.

2. Smoke Vents:

Similar to ridge vents, smoke vents are packaged with extra padding and reinforcement to prevent any damage to critical components.

3. Metal Louvers:

Each pre-assembled louver unit undergoes thorough inspection before packaging. They are wrapped and cushioned to prevent bending or distortion during transit.

Packaging Practices for Secondary Material Solutions

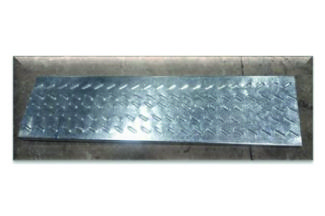

1. Steel Decking Sheets:

These heavy-duty sheets are packaged on sturdy pallets, with edge protectors and strapping to prevent shifting or damage during transport.

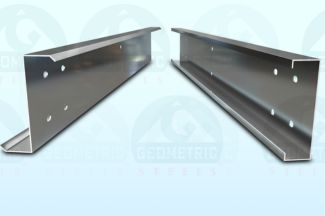

2. Purlins:

Whether it's C-purlins, Z-purlins, or specialized sections, each component is individually wrapped and labelled for easy identification. Customizable sections are packaged with additional care to ensure they arrive precisely as ordered.

3. Accessories:

From sag rods to foundation bolts, every accessory is packaged with attention to detail, with corrosion-resistant coatings applied where necessary to maintain their integrity.

Packaging Practices for Safety and Security Solutions:

1. Roof Access Hatches:

These critical access points are packaged with extra reinforcement to prevent bending or warping during transit.

2. Skylight Fall Protection:

Our fall protection systems are packaged with meticulous attention to detail, with custom crates designed to ensure they arrive ready for installation without any compromise to their structural integrity.

Sustainability in Packaging:

At Geometric Steels, we're committed to minimizing our environmental footprint. In addition to using recyclable materials for packaging, we continuously evaluate our packaging designs to optimize efficiency and reduce waste. By implementing practices such as right-sized packaging and lightweight materials, we aim to minimize the use of resources while still providing maximum protection for our products. Furthermore, we actively collaborate with our suppliers to source eco-friendly packaging materials and explore innovative solutions that align with our sustainability goals.

Conclusion:

In the competitive landscape of manufacturing, packaging isn't just about wrapping products—it's about safeguarding reputations and ensuring customer satisfaction. At Geometric Steels, our packaging practices reflect our commitment to excellence, innovation, and sustainability. By prioritizing quality at every step of the process, from production to delivery, we're not just protecting our products—we're delivering peace of mind to our customers, both at home and around the globe.